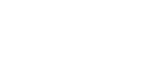

Case Study

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua. Ut enim ad minim veniam, quis nostrud exercitation ullamco laboris nisi ut aliquip ex ea commodo consequat.

John Doe – Vision Engineering

Engines

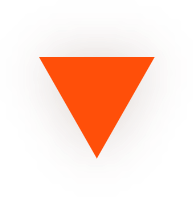

Working with both aero engine manufacturers and maintainers, our range of endoscopes inspect engine components rapidly and with minimal dismantling. Our profile projectors, vision systems, structure light scanning and Alicona surface profiling are used in the manufacture and in service assessments of engine components, providing evidence for replacement or continued use and data to support planned maintenance as well as refining designs to improve life and reduce TCO. An area of expertise is the inspection of turbine blades, checking profiles, blade roots (fir trees) and cooling holes.

Fuel Systems

Fuel valves, pumps and injectors are characterised by fine tolerances and precise dimensions, as are unions and fuel lines where long life and fuel tightness are essential. Our profile projectors and vision systems will give you dimensional assurance, backed up by our traceable UKAS approved calibrations, whilst inspecting surface finishes with our endoscopes and microscopes will evidence your manufacturing processes.

Actuators and Controls

Actuators use high pressure hydraulics and precision electronics to achieve fine control and haptic feedback to the flight crew. These safety critical components require fine tolerances to be assessed during manufacture and in service, to ensure that safety is maintained whilst ensuring optimal service lives and minimising the cost and downtime of component replacement. Our vision systems are ideally suited both to manufacturing and bench inspections whilst endoscopes enable inspections in situ with minimal dismantling. And Alicona surface profiling ensure that at a microscopic level new components are in spec and service wear can be accurately measured.

Actuators and Controls

Actuators use high pressure hydraulics and precision electronics to achieve fine control and haptic feedback to the flight crew. These safety critical components require fine tolerances to be assessed during manufacture and in service, to ensure that safety is maintained whilst ensuring optimal service lives and minimising the cost and downtime of component replacement. Our vision systems are ideally suited both to manufacturing and bench inspections whilst endoscopes enable inspections in situ with minimal dismantling. And Alicona surface profiling ensure that at a microscopic level new components are in spec and service wear can be accurately measured.

Engines

Working with both aero engine manufacturers and maintainers, our range of endoscopes inspect engine components rapidly and with minimal dismantling. Our profile projectors, vision systems, structure light scanning and Alicona surface profiling are used in the manufacture and in service assessments of engine components, providing evidence for replacement or continued use and data to support planned maintenance as well as refining designs to improve life and reduce TCO. An area of expertise is the inspection of turbine blades, checking profiles, blade roots (fir trees) and cooling holes.